brinell hardness test applications|brinell hardness number chart : import The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . Learn how to activate cheats in different editions of the game, such as SR2010, SR2020, SR-CW, SR1936, SRUltimate, SRGW and more. Find new cheats for each edition, such as cheat e=mc2 for SR2020 Update 5 and Global Crisis. See output functions for SR Ultimate and SR Great War.

{plog:ftitle_list}

WEBClub Bruges - Standard de Liège, le résumé du match. dimanche 03 décembre 2023, 18h30. Jupiler Pro League 2023-2024, 16e journée.

What are the Applications of the Brinell Method? The Brinell hardness test is used to measure and inspect materials with rough surfaces such as forgings and casting .

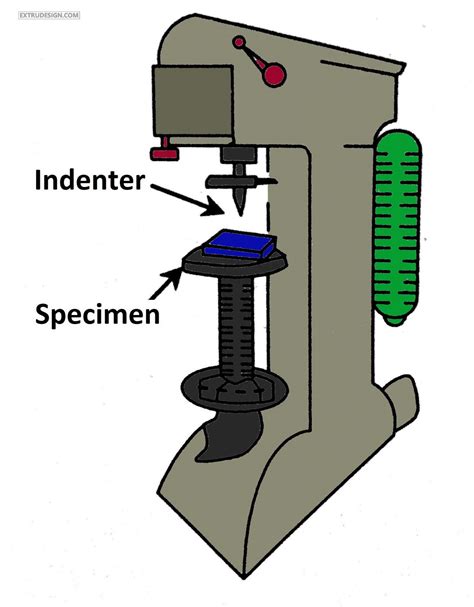

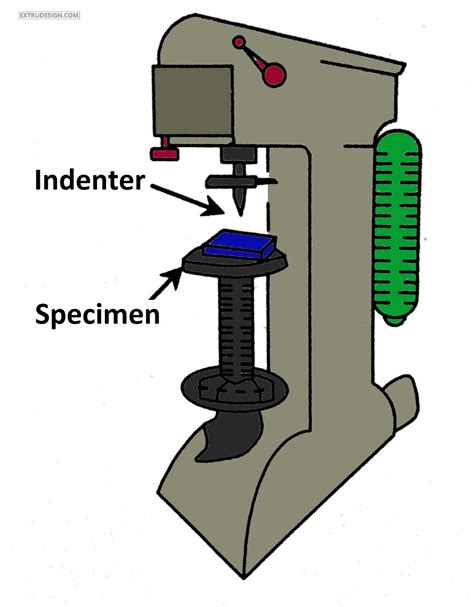

The Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for a .The Brinell method applies a predetermined test load (F) to a carbide ball of fixed diameter (D) which is held for a predetermined time period and then removed.The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and .

brinell hardness testing procedure

brinell hardness testing method

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels. Specific cases where Brinell hardness testing is applied: Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela- With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! Introduction. In many applications, components should have not only a high strength but also a high wear resistance. This generally applies whenever two or more components are in moving contact with each other. Brinell Hardness Test: This test measures the diameter of an indentation made on the surface of the material by a hard steel ball under a specific load. . Applications of Hardness Testing. Hardness testing is an essential part of quality control in the manufacturing industry. It is used to assess the hardness and durability of materials used .

Applications of Brinell Hardness Test. The Brinell hardness test is used in various industries, including automotive, aerospace, and construction. It is commonly used to determine the hardness of metals, including steel, aluminum, and copper. Additionally, Brinell hardness testing is used in the manufacturing of gears, bearings, and other .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels.SCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Characteristics and Application of Brinell Hardness. This method is well-suited for coarse or heterogeneous materials due to its large indentation area and high measurement accuracy. However, due to the large .The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages.

brinell hardness testing machine diagram

Andrew Fee, Selection and Industrial Applications of Hardness Tests, Mechanical Testing and Evaluation, Vol 8, ASM Handbook, Edited By Howard Kuhn, Dana Medlin, ASM International, 2000, . Brinell hardness test. Rockwell hardness test. Vickers hardness test. Knoop hardness test. surface condition. hardness. accuracy. calibration. case depth .Application of Brinell Hardness Test. Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness of the material which has .

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; Why Choose Us; Testing Types. Hardness Testing Basics; . Related Article: Principle and Applications of the Brinell Method.The Brinell hardness test consists of applying a constant load or force, usually between 187.5 and 3000Kgf, for a specified time (from 10 – 30 seconds) typically using a 2.5 or 10mm diameter tungsten carbide ball (see schematic in the image to your right – Figure 23.3). . Applications. Brinell hardness testing is typically used in testing . Selecting the Best Hardness Testing Method for Your Application. The following table provides an overview of various materials, including metals, along with the corresponding hardness testing methods applicable to each. . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or .Applications. Brands. Beverage Testing Equipment. . Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being .

charpy impact test data sets to download

Brinell hardness tester application: As the Brinell hardness test use large pressure, large pressure head and large indentation diameter, it is suitable for metal hardness testing of the large grain.Engineering Materials and Applications. Brinell Hardness Test Equations, Calculators and Review . The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is measured and a Brinell hardness number is calculated from . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications. Benefits and applications. The benefits of the Brinell hardness tester are wide-ranging, with practical uses across industries. . the part of a Brinell hardness testing device that presses into the material being tested, forming an indentation. Typically, the indenter is a hardened steel ball, but a tungsten carbide ball can be used when .

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . The downward distance the indenter traveled from the application of the light load to the release of the heavy load is recorded and used to calculate hardness.Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. . For example, the automotive industry often uses Brinell hardness, while precision engineering applications might rely on Vickers hardness. Converting between these two scales allows engineers . Portable and Easy to Use: The portable Brinell hardness tester is small in size, making it easy to carry and operate. It is a convenient tool for determining the Brinell hardness of ferrous metals, metals, and the tensile strength of steel products.

Brinell hardness testing methods are defined in the following standards: ASTM E10 and ISO 6506. . Lower forces and smaller diameter balls are also used in specific applications. Similar to Knoop and Vickers testing, the Brinell test applies only a single test force. After removal of the load, the resultant recovered round impression is .Brinell hardness of Aluminium is approximately 240 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for .

Brinell hardness test is slower to perform with the estimated time of 30 to 60 seconds, while Rockwell hardness is fast enough to show results in 10-15 seconds. . Application The Brinell hardness testing method is mainly used to check the hardness of soft and medium-hard materials with rough and coarse surfaces. At the same time, the Rockwell .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. . Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface of a part, small parts or small areas. .

brinell hardness testing charts

SE Palmeiras . 12 4 1 3 1 . Campeonato Brasileiro Série A Di.

brinell hardness test applications|brinell hardness number chart